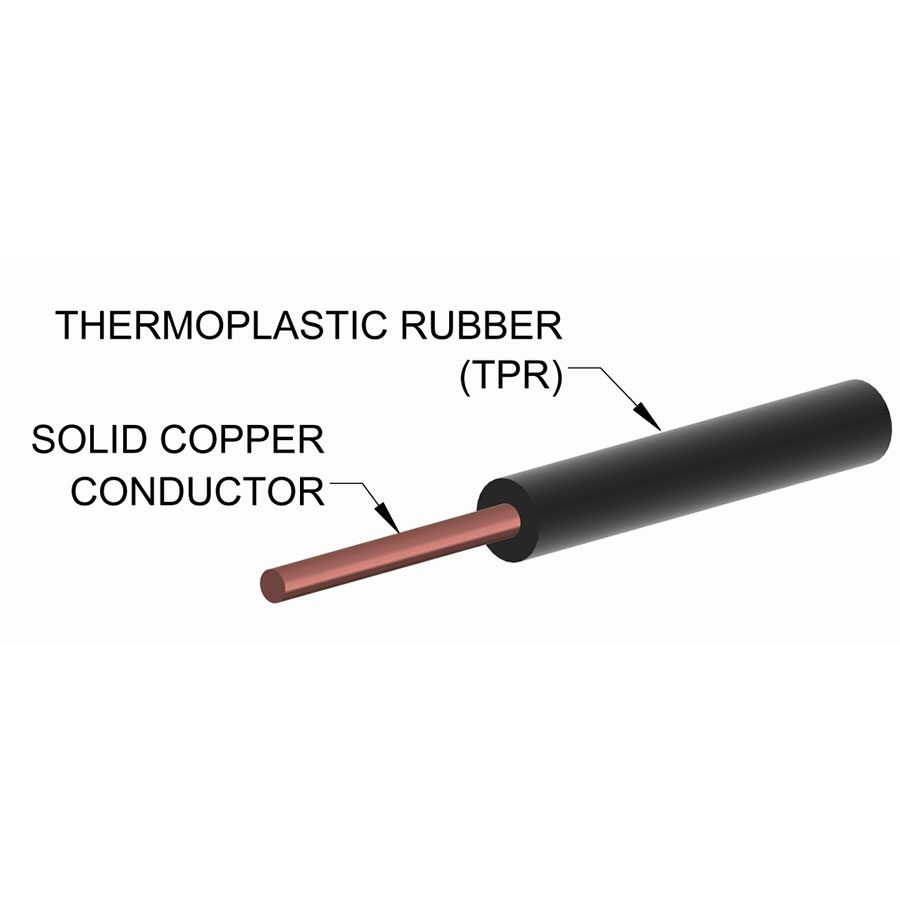

Hendrix Tap Wire

Hendrix Tap Wire incorporates the benefits of a covered cable system into a jumper/ tap wire application. Tap wire is used as a lead from primary phase conductors to equipment bushings. This is suitable for use in spacer cable, tree wire, weatherproof wire, and bare wire distribution lines. It is composed of a compressed stranded or solid copper conductor and covered with a layer of extruded black, thermoplastic rubber (TPR).

Application

- Tap wire for cutouts, transformers, and other equipment

- Substation equipment connection to provide covered bus and as a covered ground lead

- Ground wire in distribution circuits

- Commonly used with the Hendrix Wildlife Guard (BG-9), which is placed over the bushing and isolates the bushing connector from contact

Benefits

- High voltage breakdown strength, ideal for 15-35kV applications

- Reduces outages due to wildlife contact with the energized tap and a phase or a ground plane such as a transformer case

- Resists UV

- Thickest covering in the industry, yet bends with no “springback”

- Thermoplastic rubber (TPR) covering is flexible and trains easier than polyethylene covered wires

Covered Tie Wire

Covered Tie Wire is used to tie a covered conductor to a Hendrix polyethylene pin type insulator. This is suitable for use in spacer cable, tree wire, and weatherproof wire distribution lines. It is composed of a fully annealed aluminum conductor and covered with a layer of extruded black, thermoplastic rubber (TPR).

Benefits

- Eliminates tracking and erosion caused by the use of bare tie wire on a covered conductor

- Conductor and covering are flexible and have no tendency to “springback”

- Resists UV degradation

- Thermoplastic rubber (TPR) covering grips covered conductor better than PVC and other tie wires

- Tying method is the same as that used with bare conductors and ties

Insulated Ground Wire

Insulated ground wire is used on wood pole transmission lines where a bare ground wire has insufficient BIL to meet system requirements. It is comprised of a copper conductor and covered with an inner layer

of natural low density polyethylene and an outer layer of proprietary black, track and ultraviolet resistant, high density polyethylene. The covering thickness is dependent on the BIL requirements of the transmission line on which the insulated ground wire is to be installed.

Benefits

- Cost-effective method for increasing impulse strength

- Proprietary outer layer resists abrasion, electrical tracking and UV degradation

- Ideal for use on wood poles and cross arms

- Easier to install than standoff insulators

- Effective in reducing lightning outages

- Discourages copper theft

We’re Everywhere You’re Working

Easy to work with. The support you need. A team that’s on your side. We can’t wait to work with you.